030 - 3429075. Pipe Friction Coefficient g Acceleration of Gravity 98 mss Re Reynolds Number unitless k Absolute Roughness mm D Diameter of Pipe m lg Short for Log.

Pdf Effect Of Time On Pipe Roughness

How Sensitive Is Pressure Drop Due To Friction With Roughness Factor Campbell Tip Of The Month

Lab I Final Presentation

If we install a larger diameter pipe we For concrete it would be.

Absolute roughness for pvc pipe. The program uses 1 atm to convert between gage and absolute pressures. Reynolds number calculator - quick and easy calculation. When finished check that there is no damage to the glossy outer EVAL layer of the pipe.

Determine Pipe friction coefficient at turbulent flow in the most cases Colbrook Equation. On exclusive calculator page you can use the online calculator without interference from advertisements additional text links and other content that is not required for the calculations themselves. Is for aged pipe but that is accepted in design practice because it is conservative.

Perfectly smooth pipes will have a roughness of zero. For the given flow rate liquid properties and pipe size calculate the Reynolds number of flow using Equation 48. The maximum design flow depth at peak flow shall not exceed 83 of the internal pipe diameter ie.

The roughness of a pipe is normally specified in either mm or inches and common values range from 00015 mm for PVC pipes through to 30 mm for rough concrete pipes. Flowing fluid is water with density of 1000 kgm 3. For example the spacing of pipe supports on a 6 line will be approximately 6 10 16 feet.

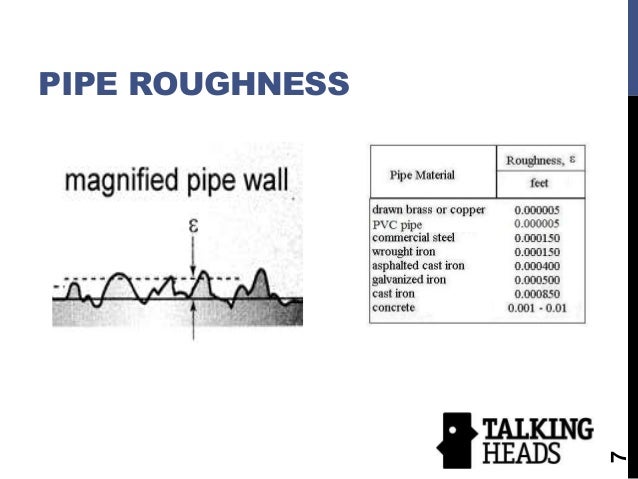

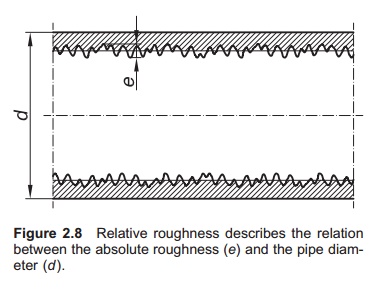

Where the absolute minimum bending radius of 3 x D is required heat should be applied as described above and then form the bend carefully. Factors affecting this include the diameter of the pipe the length of the pipe and the rate of flow litresmin amongst others. Calculate the relative roughness eD of the pipe by dividing the pipe absolute roughness by the inside diameter of the pipe.

For PVC pipe the spacing depends on the pipe schedule and operating temperature. The absolute roughness of 00018 in. Relative roughness - the ratio between absolute roughness an pipe or duct diameter - is important when calculating pressure loss in ducts or pipes with the Colebrook Equation.

R k d h 00015 10-3 m 001 m 000015. N Mannings Pipe Roughness Coefficient 0013 A Mannings Coefficient of 0013 shall be used for all design calculations regardless of pipe type and diameter. Fittings roughness of the pipe and water temperature are also factors.

Scaffolding pipe also call scaffolding tubes is the one of most popular building materials in the world. ε Pipe roughness m. If the flow is turbulent it can even depend on the roughness of the pipe walls.

The typical n value for smooth pipe concrete vitrified clay bituminous lined corrugated steel or thermoplastic is 0012. Losses due to friction will cause the pressure to decrease along the length of the pipe therefore increasing the amount of power that a pump must deliver to maintain the flow. 136430 20 x 19mm Art.

The calcuPIPE website is intended to provide design assistance only. Flexible pipe is rougher than steel pipe and therefore requires a larger diameter for the same maximum rate. Flowrates can be expressed in mass or volumetric terms.

638 inches inside whereas a May 03 2016 As PVC pipe increases in diameter the walls must also be thicker. CalcuPIPE - a simple pipe sizing resource for engineers. For a PVC pipe with absolute roughness k 00015 10-3 m hydraulic diameter d h 001 m and Reynolds number Re 10 7 - the relative rougness can be calculated as.

The number of PVC-O pipe extrusion lines is increasing in several areas of the world but especially in the Americas and Australia. From the diagram above with the relative rougness and the Reynolds number - the friction factor can be estimated to aprox. The creator of calcuPIPE takes no responsibility for the accuracy of the results.

Components 16 x 15mm Art. R k d h 1 where. 2 mm tolerance is allowed on sizes from 16 through 63 plus 0.

E Pipe roughness L. 110435 Pipe Roughness Coefficient. D Pipe diameter L.

The roughness value usually denoted as e is used in the calculating the relative roughness of a pipe against the size of its diameter. When water flows through a pipe a certain amount of pressure is lost due to friction known as friction loss. F Moody friction factor used in Darcy Weisbach friction loss equation.

A piece of bent tubing with a larger diameter will flow the same as a piece of straight tubing of smaller diameter. Includes K-values for a wide selection of fittings and valves and it has built in databases for pipe size and roughness. Local resistance can be negligible K 0.

Avoid overheating the pipe at all times. This spacing changes at high temperatures and for materials other than steel. The friction factor f can be determined using the Moody diagram shown in Figure 42 as follows.

All pipes must have the same roughness. Absolute roughness for PVC ε 00015 mm Pipe nominal diameter D 3 762 mm Relative roughness of 3 PVC pipe εD 00015 7612 197 10 -5 Next this relative roughness value can be used to determine the friction factor to be used in Darcys equation for. Relative roughness can be expressed as.

BS 67002006 Design installation testing and maintenance of services supplying water for domestic use within buildings and their curtilages Specification NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW. Pi tapes which wrap around the pipe the same way but have units in diameter can be expensive. For example for copper tubing support spacing varies from 8-ft for 1 tubing to 12-ft for 4.

Use a Mannings n of 0015 for sewers 60 inches in diameter and under and 0013 for larger sewers. It has extremely powerful and flexible units handling capabilities. For a flexible pipe the roughness is given by ɛ ID2500.

There is a minimum 895 handling fee which includes shipping. G Acceleration due to gravity 32174 fts 2 98066 ms 2. H Head losses in pipe L.

R relative roughness. Like PVC-U pipes the most suitable joint system for PVC-O pipes is a socket Sica manufacturer of plastic pipe machinery in 1998 patented EP0930148 and developed a unique socket thermoforming process for PVC-O pipes. Surface Roughness Tester With Jis 82 Jis 84 Jis 94 And B06-182 Parameters Starrett Part and Repair Information Parts may be purchased directly from Authorized Starrett Distributors.

AioFlo Pipe Flow Calculator Calculate pipe sizes flowrates and pressure drops for liquids and gases. Calculate pressure drop in round pipe with flow of 5 m 3 h pipe length 100 m internal pipe diameter of 25 mm and pipe roughness of 01 mm. Default values from Munson et al.

Introduction The choked flow calculation computes the mass flow rate through a pipe based on tank pressure and temperature pipe length and diameter minor losses discharge pressure. 21 Southland Pipe Supply Company steel pipe service center Southeast USA and Nationwide. Selectable as last item in drop-down menu saying Roughness e.

1

Slurry Pipes Dredging Services Specialising In Mini Dredgers Pump Pontoons And Layflat Hose Winders

Head Loss In Pipelines

Engineering Design System Technology On Line Resources

Pressure Drop Analysis On Water Pipe System W Pump Physics Forums

Absolute Roughness Cae Tool

Farshad S Average Absolute Surface Roughness Chart For Commonly Used Download Scientific Diagram

2